OEM 3/4 Flutes End mills nrog Ncaj Shank thiab Wave Cutting Edges

Daim ntawv thov

Lub 3 Flutes End mills nrog Straight Shank thiab Wave Cutting Edges yog tsim rau rough machining ntawm aluminium alloys, nrog rau sab machining, kauj ruam machining, thiab txoj cai kaum sab xis machining.Thiab 4 Flutes End mills nrog Straight Shank thiab Wave Cutting Edges yog tsim rau kev ua cov pa roj carbon steel, alloy steel, cam khwb cia hlau, ductile hlau, pre hardened steel, quenched steel (~ 40HRC) l, thiab lwm yam. Nws yog tsim rau kev ua sab, kauj ruam ua, thiab txoj cai kaum groove ua.

Specifications

Cov khoom siv raw rau kev tsim cov 3 flutes kawg zeb yog UK10, nrog cov milling cutters muaj nyob rau hauv diameters li ntawm 6 hli mus rau 20 hli, thiab tag nrho cov cuab yeej ntev li ntawm 50 hli mus rau 100 hli.Lub kaum sab xis ntawm lub clutter yog 45 degrees.

Cov khoom siv raw rau kev tsim cov 4 flutes kawg zeb yog UK30, coated nrog ATN.Lub kaum sab xis ntawm qhov sib tsoo yog 30 degrees, thiab sab nraud ntawm lub milling cutter muaj nyob rau hauv thaj tsam ntawm 6 hli mus rau 20 hli.Tag nrho qhov ntev ntawm lub cutter yog 50 mm mus rau 100 mm.

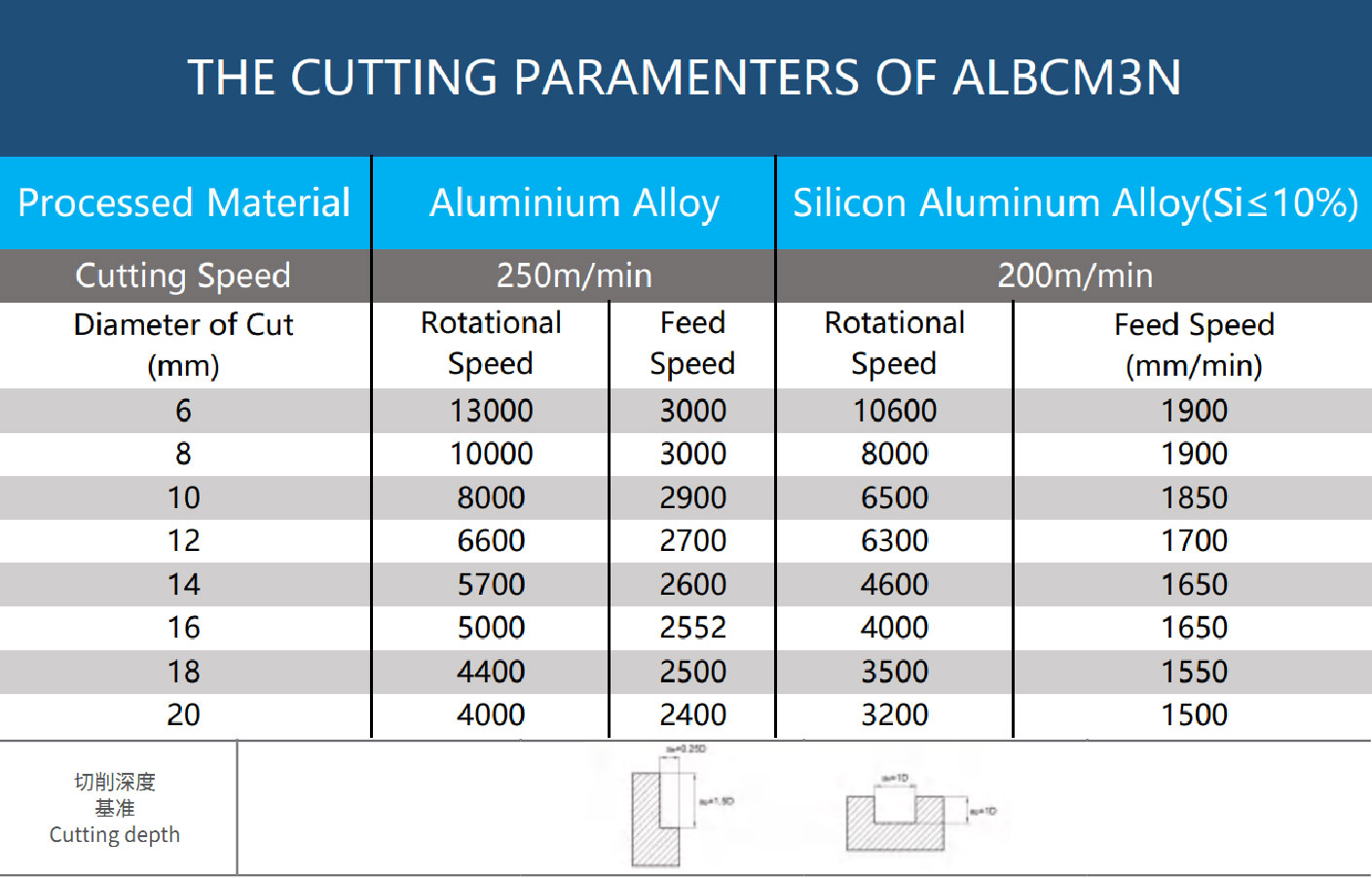

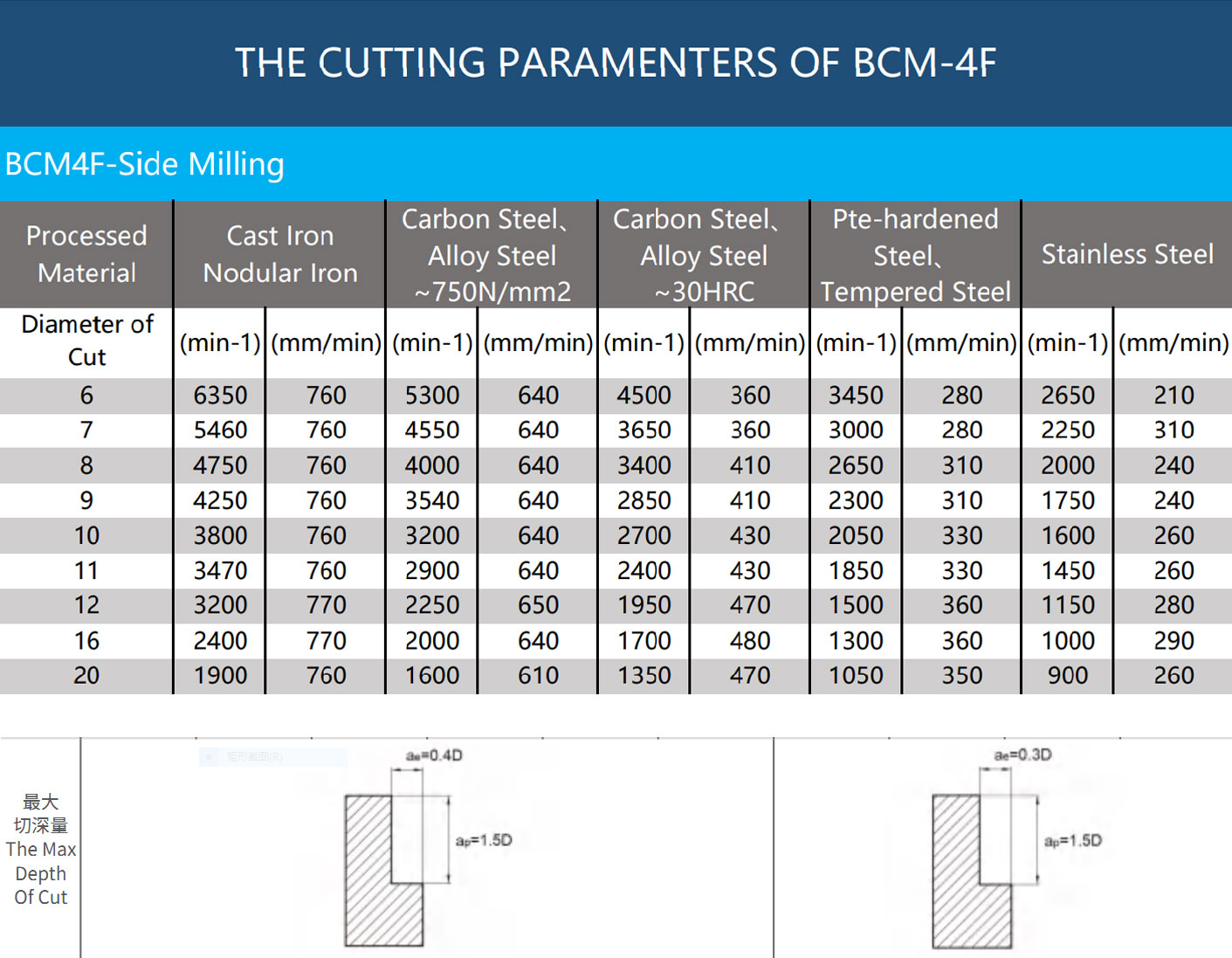

Qhov txiav paramenters ntawm ABCCM3N / BCM4F

1. Thaum txiav qhov tob me me, qhov kev sib hloov ceev thiab pub ceev tuaj yeem txhim kho ntxiv

2. Dej soluble txiav kua yog pom zoo

3. Nto milling raug pom zoo

4.Nyob rau hauv cov xwm txheej ntawm lub tshuab thiab workpiece installation rigidity yog tsis zoo, uas yuav tsim kev co thiab txawv txav suab, nyob rau hauv lub sij hawm no yuav tsum ceev ceev ceev thiab pub ceev.

5. Lub ncua kev ncua ntev ntawm lub cutter yuav tsum luv li sai tau.

6. Lub rooj sab sauv yog raws li tus nqi siv ntawm sab txiav.Cov xwm txheej txiav rau qhov milling yog raws li 70% ntawm kev txiav ceev hauv cov lus saum toj no thiab 50% ntawm kev pub ceev

1. Thov siv cov cuab yeej siv tshuab ua haujlwm siab thiab cov cuab yeej ua haujlwm.

2. Thov siv cua txias los yog txiav cov kua dej uas tsis nquag ua kom muaj pa taws.

3. Smooth txiav yog pom zoo rau sab txiav.

4. Thaum lub installation rigidity ntawm lub tshuab cuab yeej ua hauj lwm piece yog tsis zoo, kev co thiab txawv txav suab yuav tshwm sim.Ntawm no

lub sij hawm, qhov ceev thiab pub ceev nyob rau hauv cov lus saum toj no yuav tsum tau txo xyoo-rau-xyoo.

5. Lub ncua kev ncua ntev ntawm lub cutter yuav tsum luv li sai tau.